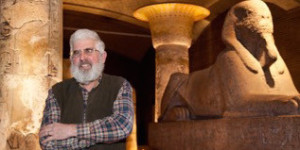

Today we have a guest post from Mark Rashap, CWE. Mark has some insights about tasting saké in the context of the language of Champagne, and shares some of his adventures from his latest trip to Japan.

…

Saké has always been sort of an enigma for me. I’ve liked it and attended many classes and conference seminars on it; however, there’s something utterly confusing about the dizzying Japanese characters and multitude of production techniques. It has always seemed like I’ve lacked the vocabulary for describing the subtle and elusive flavors, as well as not being able to correlate those flavors to a particular place or terroir.

Here’s where the enigma deepens: is this not essentially our goal as wine tasters? We try to see how the terroir speaks to us out of the glass, discern whether it is typical or atypical of that region, attempt to understand why by digging into the growing and production techniques, and the world goes on.

Saké, however, abides by different rules and should be thought of more in terms of “house style” instead of terroir, not unlike the large negociant houses in Champagne. In fact, the more I thought of saké in terms of Champagne, the more insight I gained in understanding this ethereal beverage. With this understanding, I was able to develop a vocabulary around which to describe sakes previously elusive aromas and flavors.

…

This is not to say that a sense of place is not important in sake. Granted, the rice, albeit from specified varieties grown for saké, does not have to come from any region in particular and is often shipped all around the country. However, certain saké breweries (Kura) have congregated around areas known for pure and reliable water supplies, such as the Fushimi area in south Kyoto and the mountainous area of Niigata. Additionally, there is some regional component to the Saké brewer (Toji) guilds. Nevertheless, there are no AOC–type rules to preserve regionality or history, and we can confidently say that the mark of the Toji is the most defining factor in the quality and subtlety of the final product. This is not unlike the Negociant houses of Champagne priding their flavor and style around the blending skill of Chef de Cave or their unique house yeast strain.

Real Japanese Saké, or Nihonshu (technically “saké” is just the Japanese work for alcohol in general), has an identity crisis in the US. The process is most similar to brewing beer; however, the lack of carbonation, alcohol content, potential complexity of flavors, and ability to pair with various food align more with wine. However, when we start seeing descriptions such as nuts, red fruit, flowers, and yeastiness in describing a clear and pristine liquid, it is all to reminiscent of Champagne. I’m particularly talking about Junmai, which does not have alcohol added and consists of only rice, water, yeast, and kōji (the mold that converts the starch in rice to fermentable sugar), and Ginjōshu, meaning the rice was polished, removing 40-65% of the outer layer of rice (this is where the impurities are found).

…

John Gaunter, one of the best resources on Saké in the English language, writes in his Saké Handbook, “A vast number of words describe the kaori, or fragrance of a saké. These are often simple fruit, flower, or rice-like sensations, with esters, earthy tones, and herbal notes as well.” Additionally, he frequently uses terms such as “austere” on one end of the spectrum and “gentle and soft” on the other, Krug vs Perrier Jouët perhaps?

In relationship to acidity in sake (which is much lower than in the world of Champagne), Gaunter writes, “a higher acidity often makes a sweeter saké taste more dry, while a lower acidity can make a saké seem heavier on the palate.” Sounds like the acidity/dosage balance that Champagne winemakers strive for come disgorgment time. In the Saké Handbook, Gaunter gives over 50 recommended sakés with descriptions and for each and every one, you could replace the word saké for Champagne, and it would still make sense.

This link to Champagne really helped me in a recent visit to the Fushimi district of Kyoto, where I tasted almost all of the 17 breweries there. I am constantly befuddled and enamored by the sakés (and Champagnes) that show the red fruit and plum aromas commonly found in the villages of Aÿ, Ambonnay, and the greater

…

Montagne de Reims. I found the Shoutoku brewery with their famous Junmai’s to pertain to this style. Furthermore, I tasted many sakés that showed an austerity, earthiness, chalkiness, and white flowers that is haunting and quintessential of Les Mesnil Sur Oger and the greater Cotes de Blanc. Kinshi Masamune pertaining to this camp. Practically ever saké I tasted reminded me of something in the world of Champagne, either a village or producers or flavor I tasted once upon a time.

As wine professionals, we should strive to continuously improve our vocabulary in the way that makes sense for us. Whether this means using Ann Noble’s Wine Aroma Wheel or Matt Kramer’s intangibles of insight, harmony, and surprise. In my opinion, studying Champagne and learning to describe it, which should be an absolute pleasure for all of us, trains us to bridge these lexicons and identify the tangibles of yeast, nuts, floral and fruit components as well as speaking in metaphor, because there is an undeniable other-worldliness of Champagne. To my knowledge, I have never read of the saké-Champagne link before and can consider it an original concept. My only hope in writing about this is that it helps you engage in the world of saké with a certain familiarity and comfort, ultimately allowing you to further explore its complexity of flavors and aromas. I’d love to hear if you agree!

Post authored by Mark Rashap, CWE. Mark has, over the past ten years, been in the wine world in a number of capacities including studying wine management in Buenos Aires, being an assistant winemaker at Nota Bene Cellars in Washington State, founding his own wine brokerage, and working for Texas-based retail giant Spec’s as an educator for the staff and public.

Post authored by Mark Rashap, CWE. Mark has, over the past ten years, been in the wine world in a number of capacities including studying wine management in Buenos Aires, being an assistant winemaker at Nota Bene Cellars in Washington State, founding his own wine brokerage, and working for Texas-based retail giant Spec’s as an educator for the staff and public.

In August of 2015, Mark joined the team of the Society of Wine Educators as Marketing Coordinator to foster wine education across the country.

Are you interested in being a guest blogger or a guest SWEbinar presenter for SWE? Click here for more information!